Description

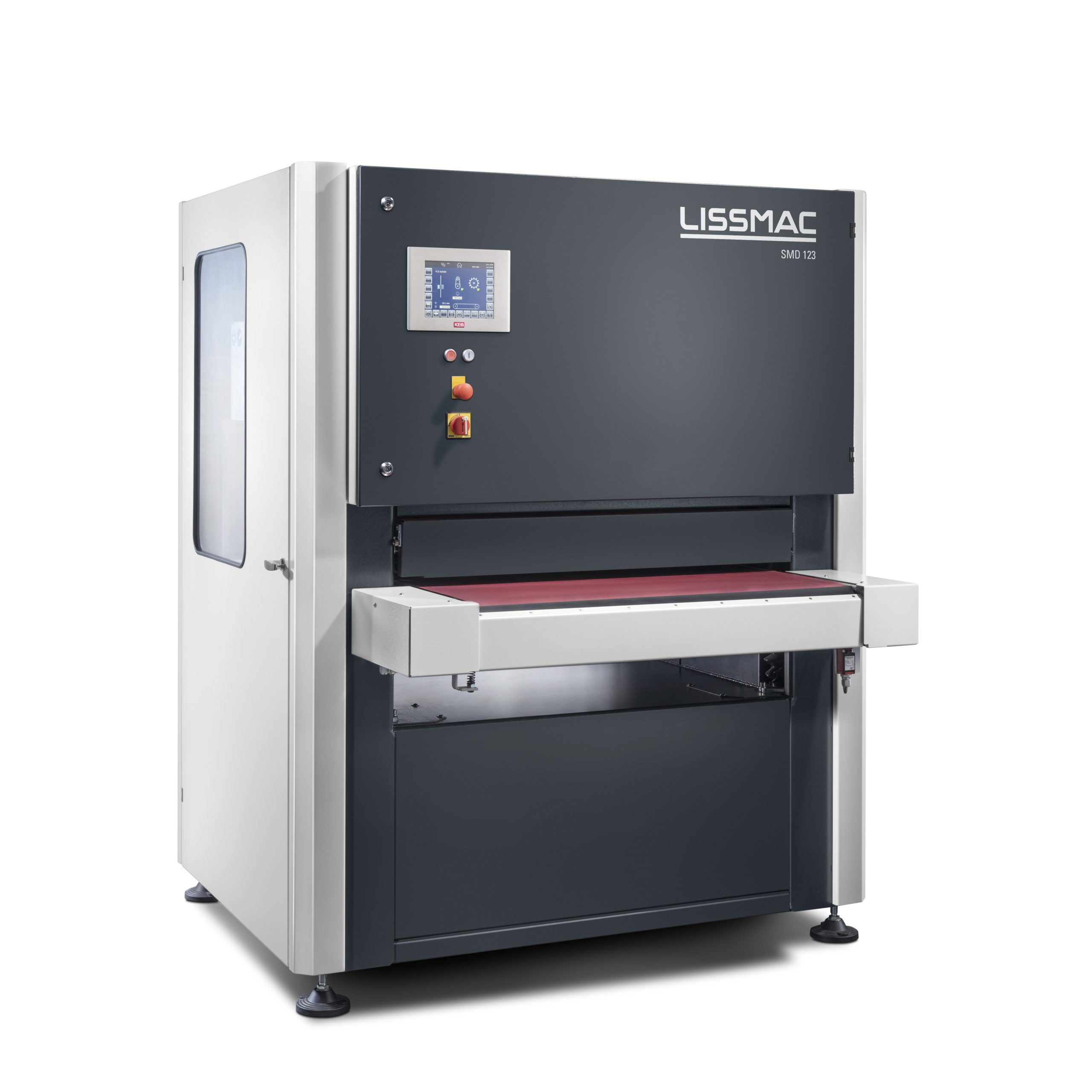

A cost-effective deburring machine the SMD 123 RE offers great results in sheet metal deburring and surface finishing. Low-cost tooling options, simple operation and efficiency are the key benefits of adding this edge rounding machine to your workshop.

The SMD 123 RE is a compact deburring machine that removes the top burr on laser, flame and plasma cut (or punched) parts.

A compact and versatile deburring machine

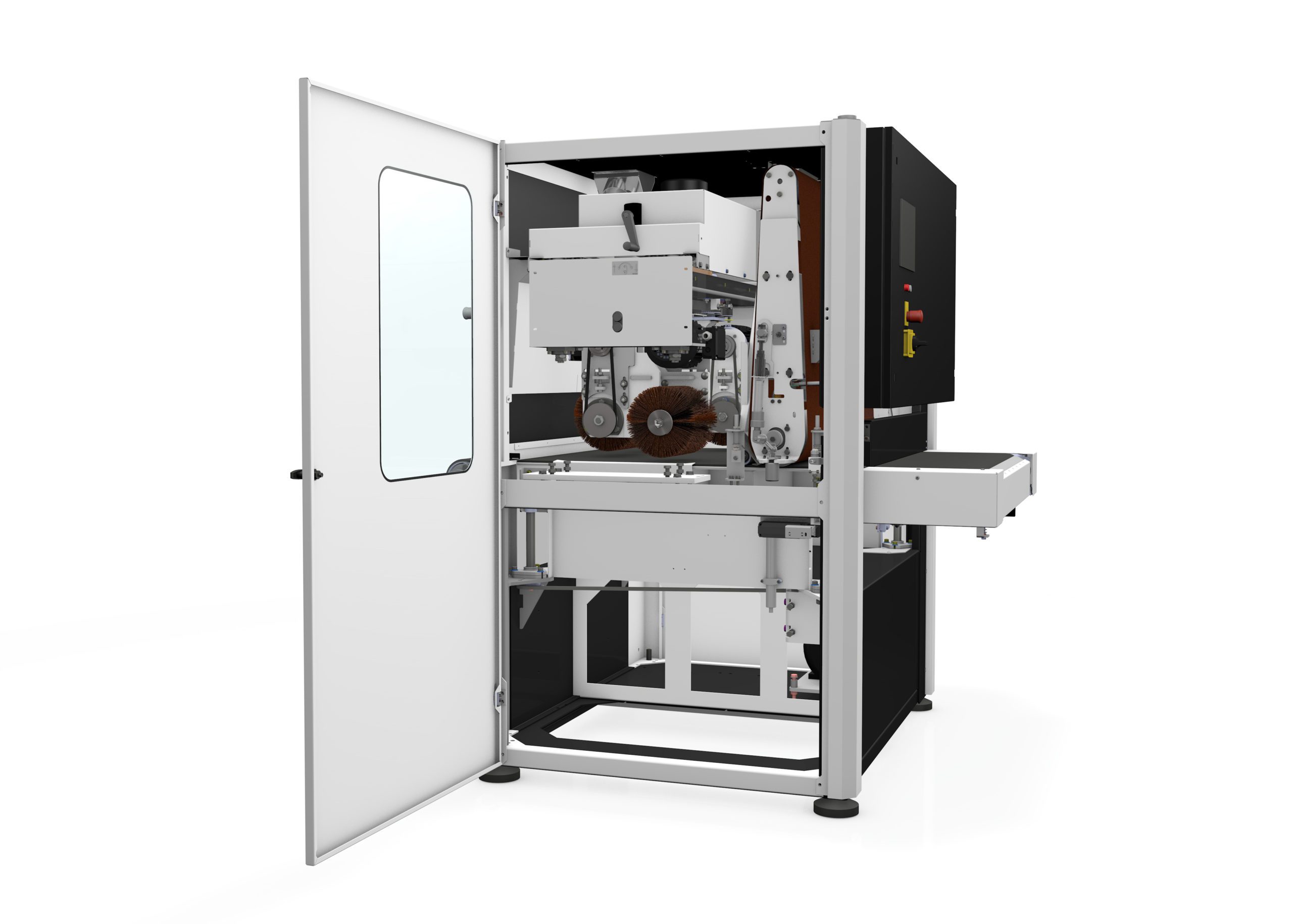

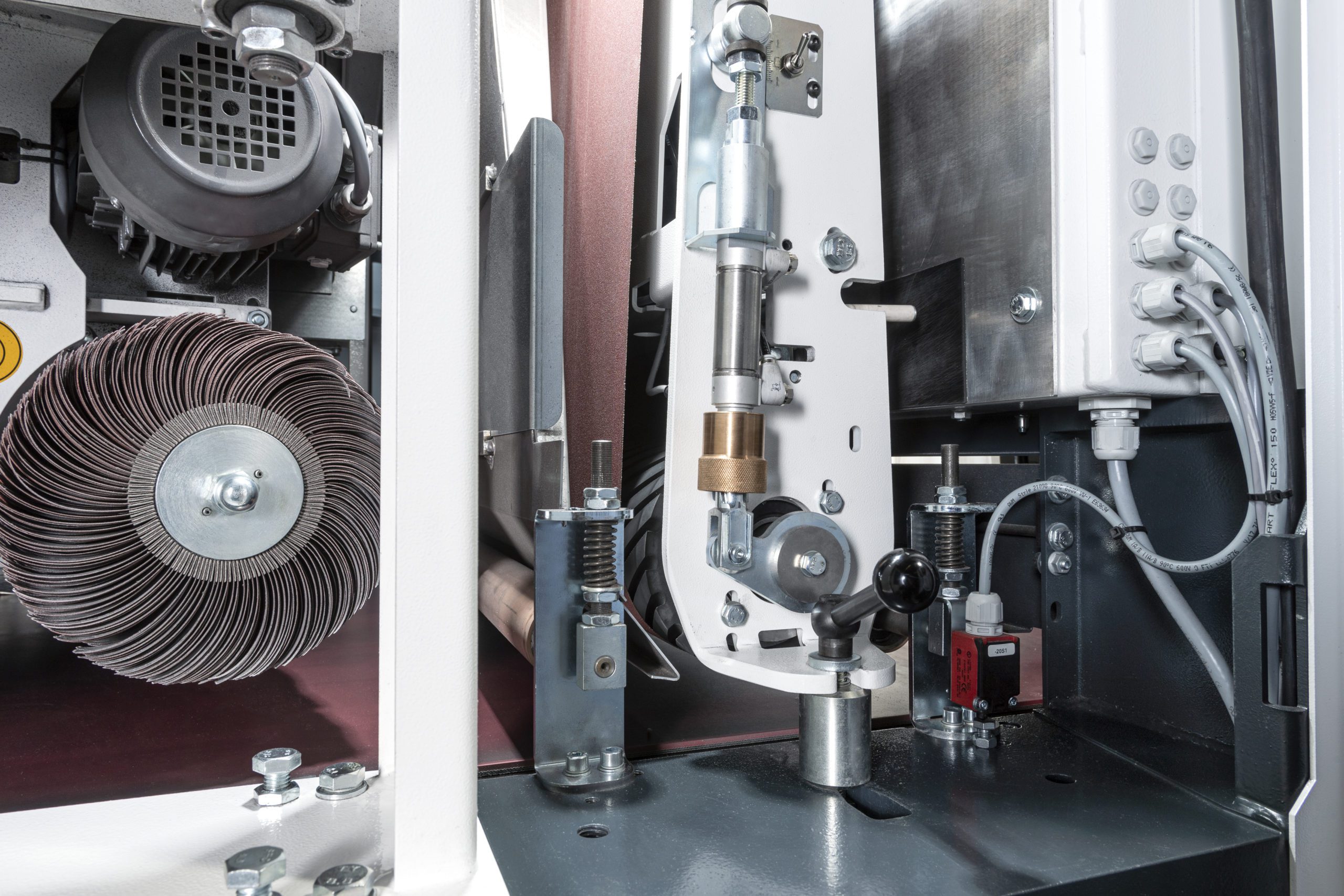

One abrasive belt in the first position helps to remove vertical burrs from the cutting process and the rotary brush system in this edge rounding machine makes parts safe to handle whilst maintaining a multi-directional and pleasing finish.

Make parts safe-to-handle

As our focus moves towards improving conditions in the workplace we have to consider making metal components safe-to-handle. The Lissmac SMD123RE edge rounding machine makes this happen in a time-efficient manner that improves the existing working conditions of all those involved in processing parts on this deburring machine. When used with a wet or dry dust extractor, air quality in the workplace is also much better.

- Deburring machine

- Edge rounding machine

- Versatile entry level machine

- Removal of burrs

- Two rotary brushes for consistent edge-rounding and uniform surface finishing

- Surface polishing without complex set-up

- Suitable for steel, stainless steel and aluminium

- Suitable for parts with up-forms

- Touch panel for intuitive operation

- Individual operation of belt and brush positions – machine can run with one or the other (or both)

- Stepless grinding belt speed

- Space efficient footprint

Technical Data

| SMD 123 RE | |

|---|---|

| Working width max. | 950mm |

| Workable material thickness | 1.0 – 50 mm |

| Load | 200 kg/rm |

| Voltage | 400 V / 50 Hz |

| Network Structure | 3~ PEN / 3~ PE+N |

| total current consumption | 42.3 A / 42.7 A |

| total power | 19.9 kW / 20.3 kW |

| insulation class | IP 42 |

| infinitely variable feed speed | 0.5-8 m/min. |

| weight approx. | 1750 kg |

| dimensions (W/D/H ) approx. | 1600 x 1800 x 1900 mm |