Description

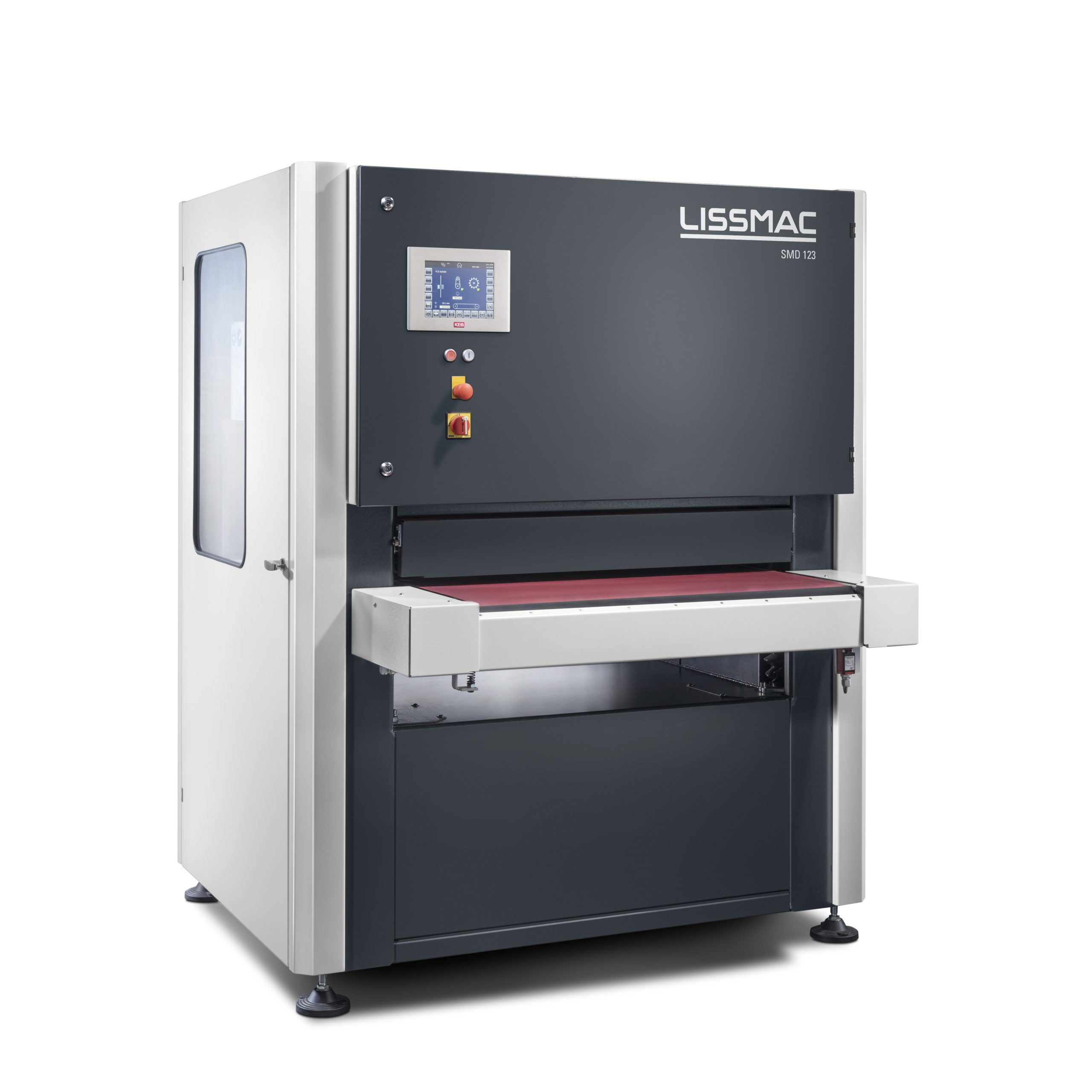

A cost-effective machine the SMD 123 RE offers top machining results in sheet metal deburring and surface finishing. Low-cost tooling options, simple operation and energy efficiency are the key benefits of adding this machine to your production portfolio.

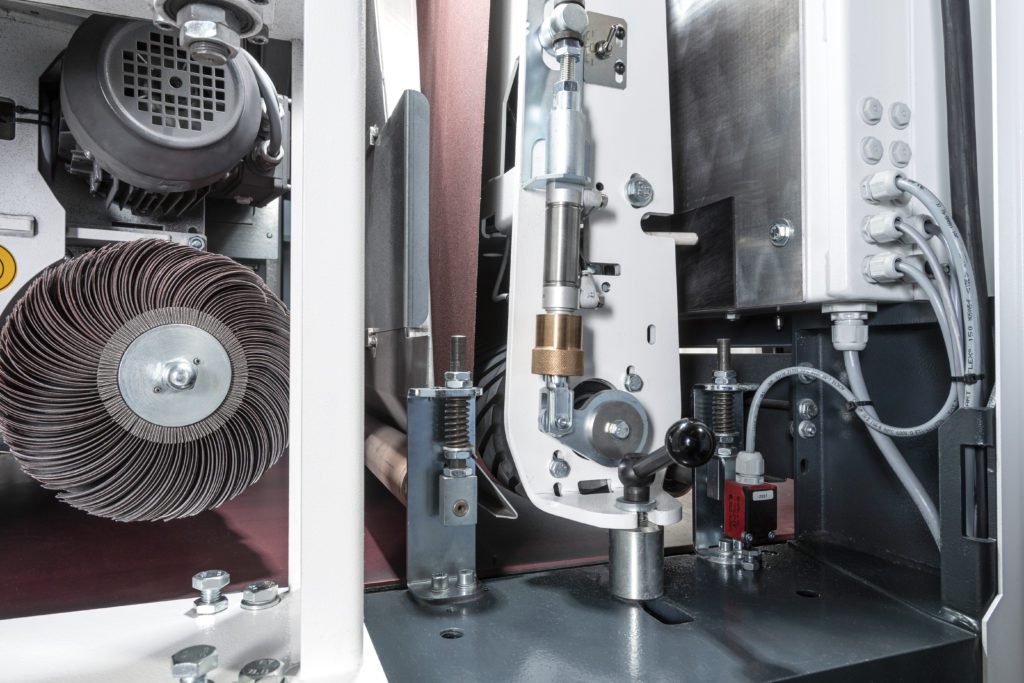

The SMD 123 RE is a compact unit that removes the top burr on laser, flame and plasma cut (or punched) parts with an abrasive belt in the first position followed by a rotary brush head to the rear that deburrs and edge-rounds external and internal edges leaving a multi-directional finish, perfect for powder-coating preparation.

- Versatile entry level machine

- Removal of burrs

- Two rotary brushes for consistent edge-rounding and uniform surface finishing

- Surface polishing without complex set-up

- Suitable for steel, stainless steel and aluminium

- Suitable for parts with up-forms

- Touch panel for intuitive operation

- Individual operation of belt and brush positions – machine can run with one or the other (or both)

- Stepless grinding belt speed

- Space efficient footprint

[ Video ]

Technical Data

| SMD 123 RE | |

|---|---|

| Working width max. | 950mm |

| Workable material thickness | 1.0 – 50 mm |

| Load | 200 kg/rm |

| Voltage | 400 V / 50 Hz |

| Network Structure | 3~ PEN / 3~ PE+N |

| total current consumption | 42.3 A / 42.7 A |

| total power | 19.9 kW / 20.3 kW |

| insulation class | IP 42 |

| infinitely variable feed speed | 0.5-8 m/min. |

| weight approx. | 1750 kg |

| dimensions (W/D/H ) approx. | 1600 x 1800 x 1900 mm |