Description

A 1500mm working width deburring machine with constant throughput height that can be seamlessly integrated into automated production lines with multiple processing steps…

Not just another deburring machine…

The Super 1500 is the versatile deburring machine for sheet metal parts with a working width of up to 1500 mm. Whether removing slag, burrs, edge rounding, laser oxide removal or creating a perfect finish, the Super 1500 performs all these operations in a single pass of the machine.

The feed table always remains at a fixed height on this deburring machine, regardless of the thickness or dimensions of the workpieces being processed. It eliminates complexity and ensures a uniform connection between machines within one production line. This makes the Super 1500 not just another deburring machine, but a strategic part of your production infrastructure.

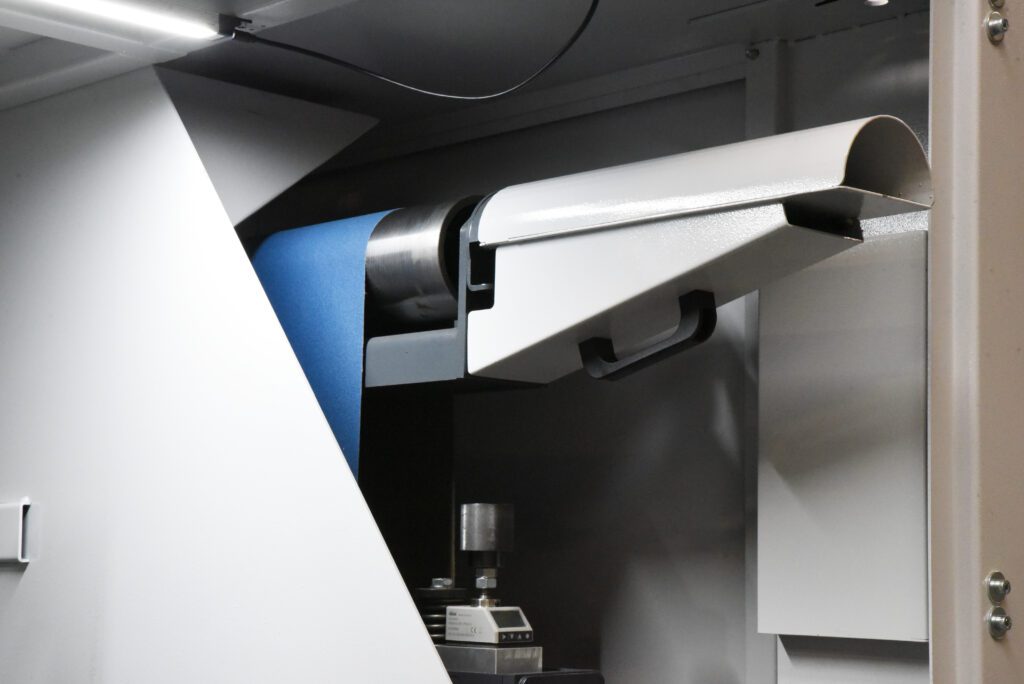

The grinding belt is designed to remove hard burrs effectively, without damaging the workpiece surface. Thanks to extra-large contact rollers and precise depth and pressure control, each operation is optimally tuned, ensuring consistent oxide removal with high-quality results.

- Edge rounding

- Laser oxide removal

- Heavy slag removal

- Finishing – straight grain finish

- Controlled roughness

- Polishing

- Deburring

Grinding belt (K)

The grinding belt is designed to remove hard burrs effectively, without damaging the workpiece surface. Thanks to extra-large contact rollers and precise depth and pressure control, each operation is optimally tuned, ensuring consistent, high-quality results.

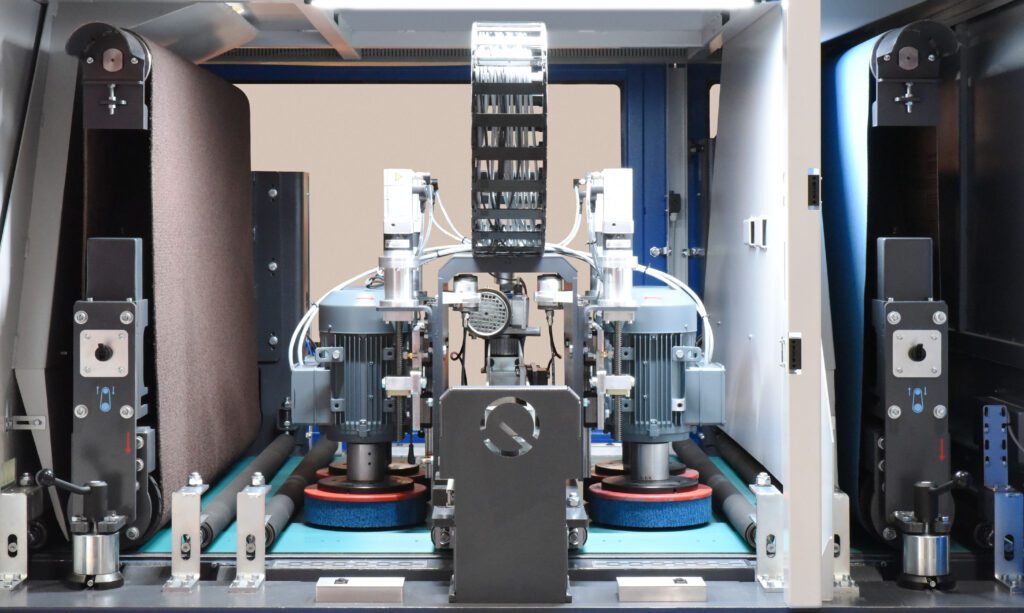

TopBrush system (4PTB)

Mount different types of brushes on the advanced TopBrush system on this deburring machine, allowing you to perform multiple operations simultaneously. Whether it’s edge rounding, oxide removal or surface finishing, this versatility gives you unprecedented possibilities.

Oscillating brush system for perfect oxide removal:

The brush unit has 2 top brushes. 1 counterclockwise and 1 clockwise. The 2 stations, each with a large top brush, can move across the entire belt width. The setting of this stroke can be short or long. This allows both small and large cut parts to be deburred, rounded and finished perfectly. The brushes are easy to change and can be adjusted individually. Combinations of different types of brushes on 1 line can considerably shorten the production process in 1 pass.

Touch Screen Controls

Equipped with an intuitive touchscreen that allows the operator to easily set and save programmes. This ensures faster settings, less downtime and higher efficiency in your work process.

Advanced Control System (optional, very highly recommended!)

The optional Advanced Control provides CNC control for precise adjustments of grinding pressure and brush height, with automatic measurement of TopBrushes and calibration after brush changes. On-the-fly wear compensation continuously monitors tool wear and automatically adjusts settings, without interrupting the process. In addition, programme storage provides quick access to preset operations, minimising changeover times.

For further information on this machine please visit VG Machines website click here

For other machines in the VG range from FINAIDS please click here