Description

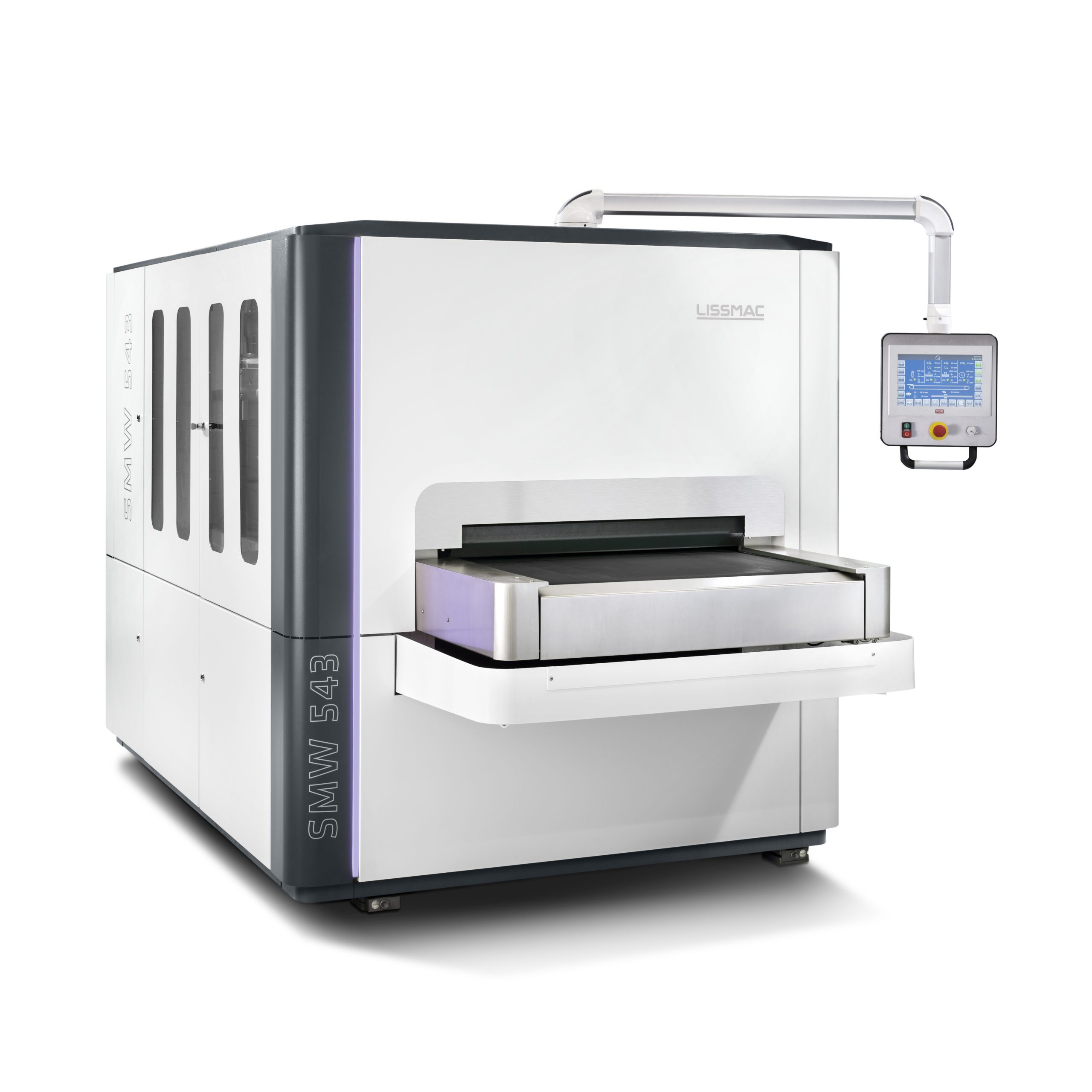

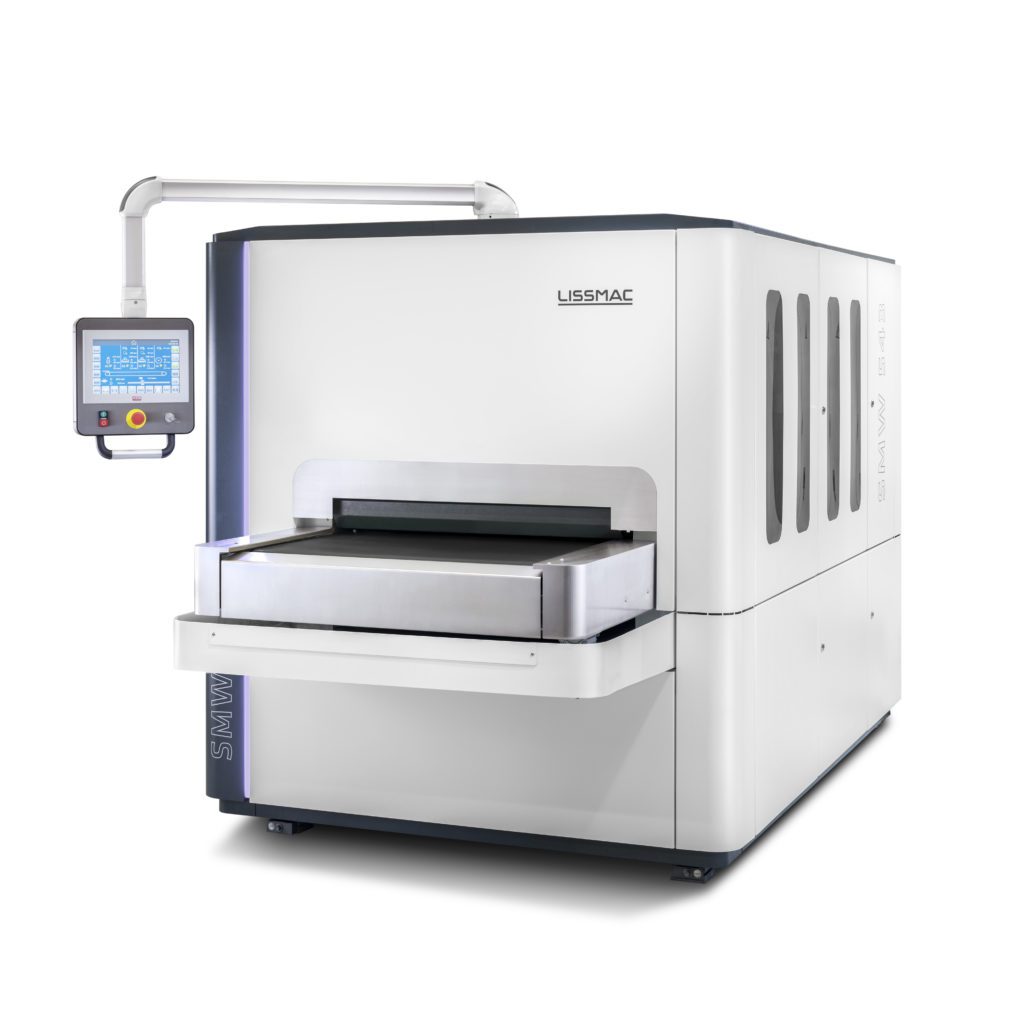

A wet processing and polishing machine that offers maximum protection when grinding aluminium, titanium or super-fine polishing of stainless steel.

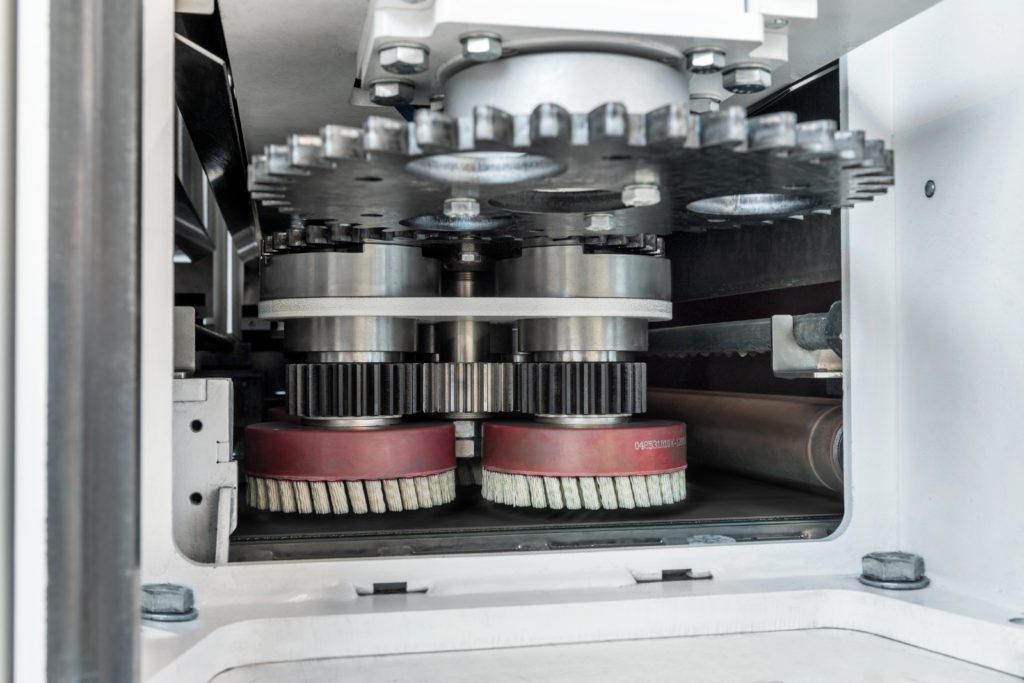

An abrasive belt removes vertical burrs on the peripheral edges of the processed part and planetary brushes continue deburring more complex parts before being finished by a non-woven roller brush before exiting the polishing machine. The brushes can be configured to assist in achieving the finest possible finish this wet polishing machine is capable of. A stunning design makes a great addition to your manufacturing environment whilst maintaining Lissmac’s reputation for being a safe and simple-to-operate machine.

SMW 5 Wet Polishing Machine Features:

- Wet grinding and wet polishing machine

- Removal of burrs

- Two banks of 12 planetary brushes to remove internal burrs and radius edges

- Self-contained wet system – NO EXTRACTION NECESSARY

- Suitable for steel, stainless steel, aluminium, titanium and magnesium

- Suitable for parts with up-forms

- Touch panel for intuitive operation located on swinging arm

- Capable of cleaning greasy and oily parts whilst processing

- Safe machining of volatile materials

- Wet process reduces heat generation in processed parts

For more information, technical assistance or quotation please contact sales@finaids.com

Technical Data

| SMW 5 | |

|---|---|

| Working width max. | 950, 1350, 1650mm |

| No. of heads | 1 – 4 |

| Sheet thickness | 0.5 – 120mm |

| Voltage | 400 V / 50 Hz 480 V / 60 Hz |

| Network Structure | 3~ PEN / 3~ PE+N |

| Insulation class | IP 42 |

*infinitely configurable machine for customer requirements

Downloads

General Product Information

Data Sheets

Instruction Manuals & Spare Parts

For more information on the Lissmac range from FINAIDS please click here

For more information on Lissmac Machines please visit their website here