Description

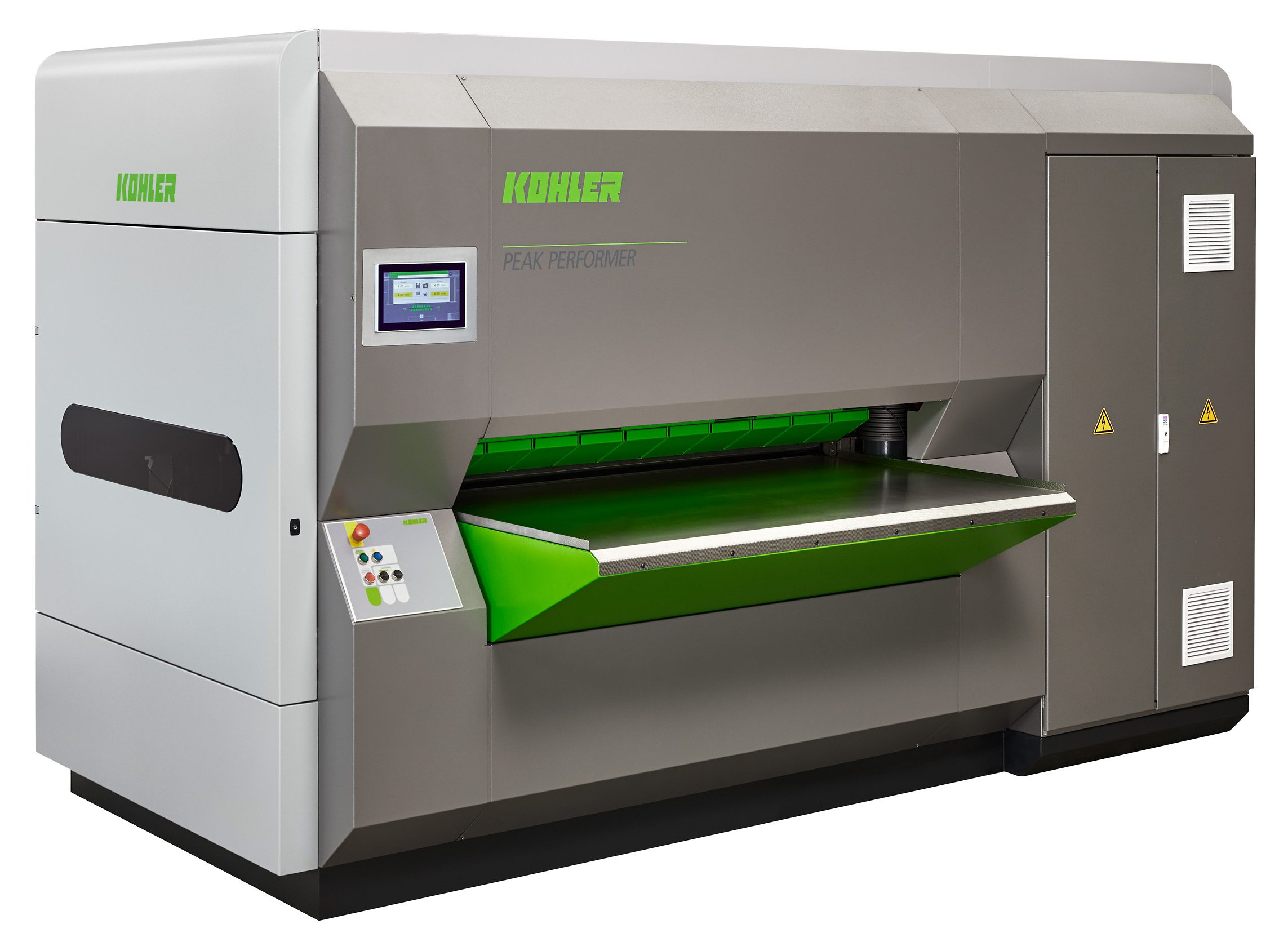

Flattening and de-stressing sheet metal: optimum leveling results and excellent efficiency.

The Peak Performer part leveling machine from KOHLER reliably and precisely levels and relieves stress from sheets and part blanks. Your downstream production processes benefit from higher quality leveled parts and sheets, as there’s no need for time-consuming, manual rework.

Product highlights:

- Servo-electronic machine concept without hydraulics

- Electromechanical leveling gap control (patented)

- Advanced cleaning system

- Reversible leveling rollers (patented) to return parts to start if required

- Innovative control system

- Predictive maintenance prevents machine down-time

KOHLER’s part leveling machines have no hydraulic systems whatsoever, which means that coupled with their excellent energy efficiency, they play an active role in saving resources in industrial sheet metal processing. KOHLER is breaking new ground and confirming its position as the market leader with its use of direct drives and electromechanical leveling gap control in hydraulic-free part leveling machines.

The KOHLER Peak Performer part leveling machines level sheets that are 0.2 to 66 mm thick.

Quality-focused companies from a wide-range of industries, such as those listed below, rely on part leveling machines from Kohler:

- Automotive engineering

- Construction and Agricultural Machinery

- Mechanical Engineering

- Steel Service Centers

- Housing construction

The importance of part leveling in metal fabrication

Flat parts can boost bending and welding productivity and keep customers happy!

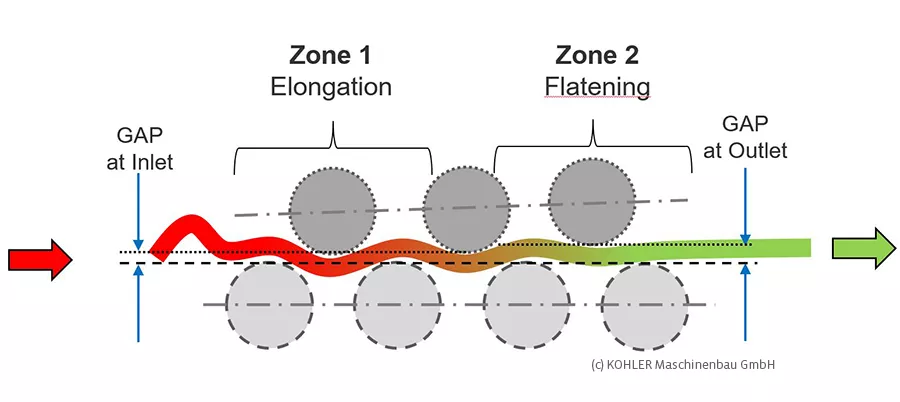

The sheet metal and plate that gets delivered to a metal fabricating company looks flat enough. But looks can be deceiving, and that is especially true with metal. What might seem flat at first is likely to lose its flatness during fabricating. This makes sense when you consider what happens to the raw material before it’s delivered to the shop. Sheets and plates come from the mills in coils. In metal service centers, these coils are uncoiled, straightened, and finally cut to length. Although the sheets appear to be flat, they still have stress inside. (The stress is evident in the material’s grain.)

What are metal fabricators to do to combat the stresses introduced during coiling and released after the parts have been cut or punched? This is where a part leveling machine can help. What are metal fabricators to do to combat the stresses introduced during coiling and released after the parts have been cut or punched? This is where a part leveling machine can help.

For more information on the Kohler range please click here

For more information on capital machinery sold by FINAIDS please click here