Description

Highly effective deburring on both sides and even edge rounding for punched, laser and fine plasma cut workpieces in just one operation.

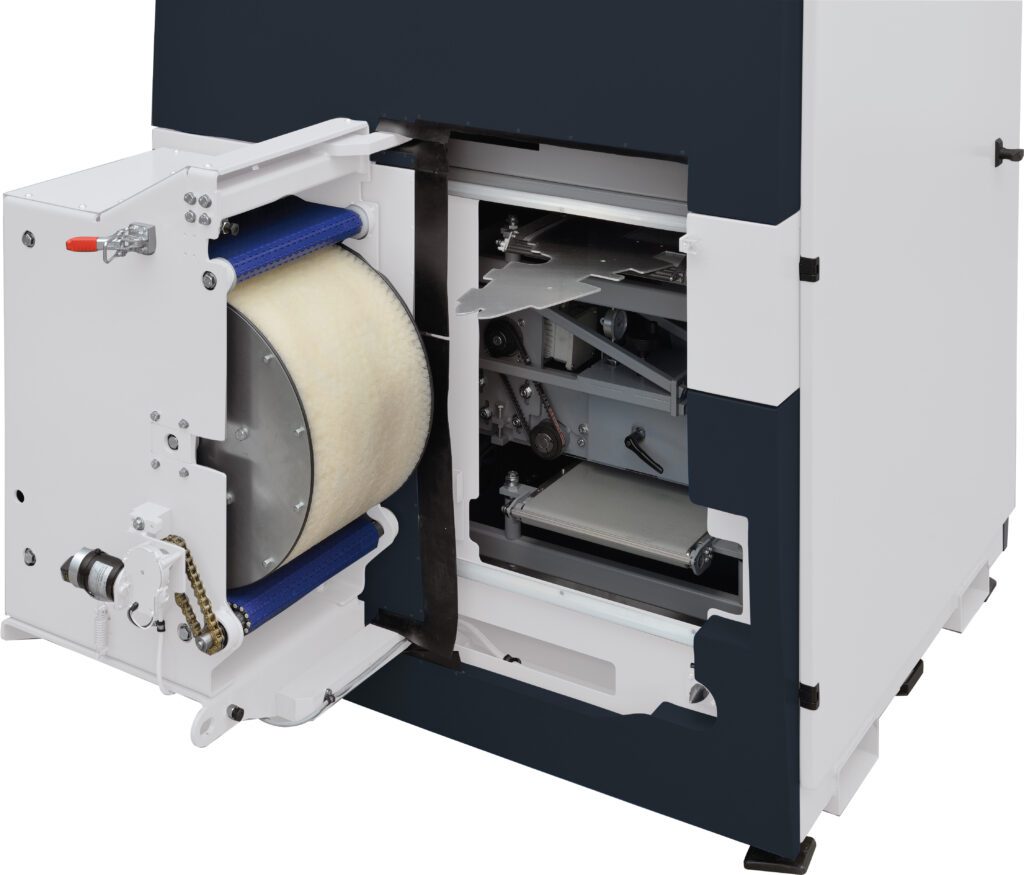

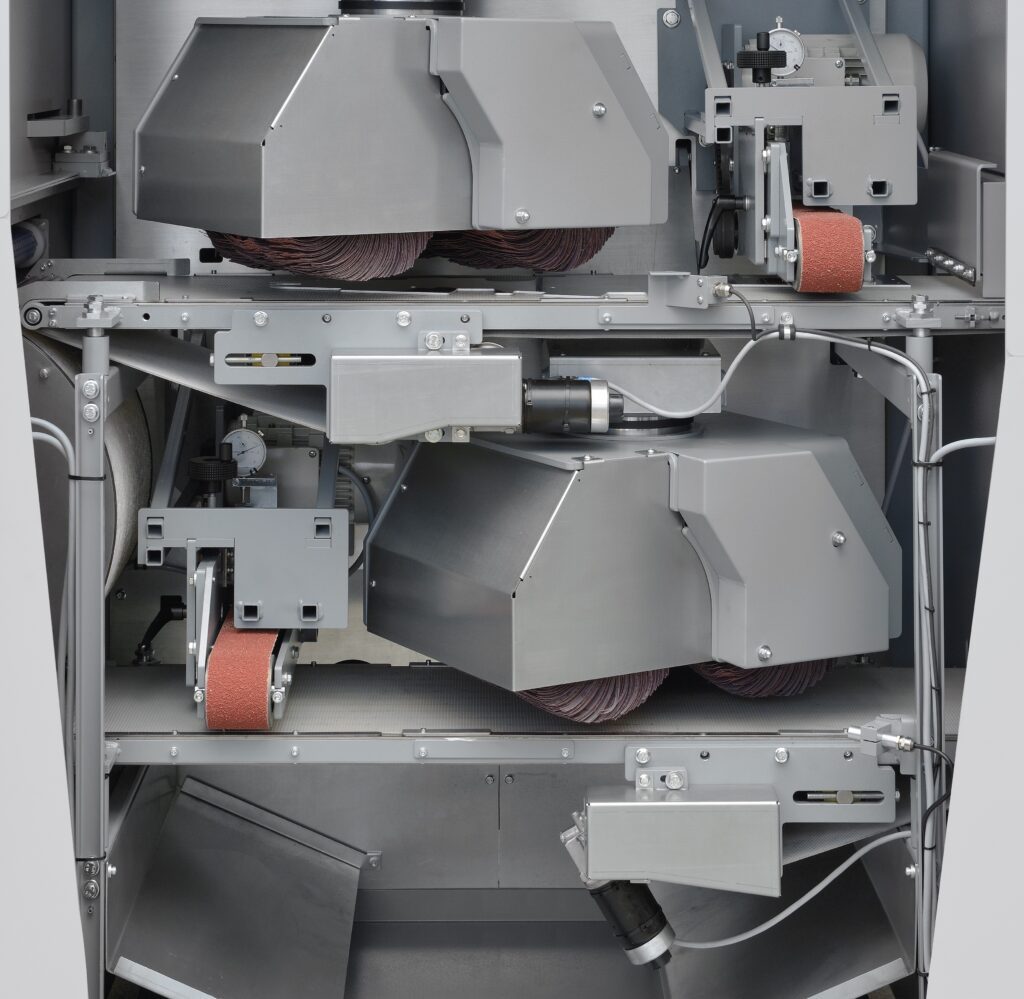

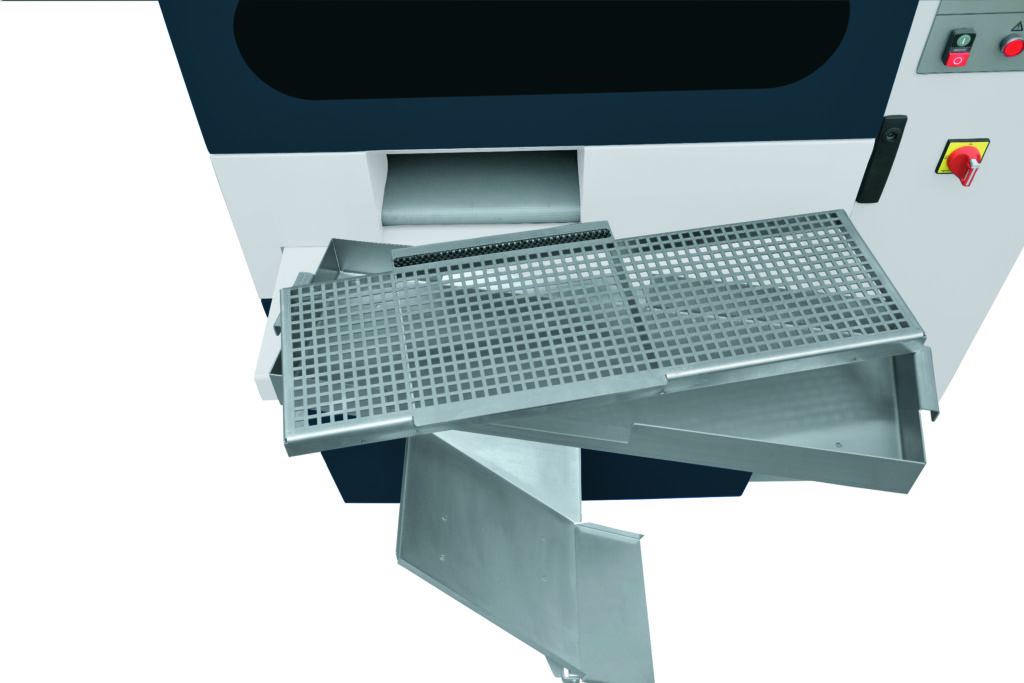

The SBM-XS G1E1 grinding machine is used for effective sheet metal processing. It was designed to process small parts as well as for processing on both sides and for a directionless finish in the field of metal processing. With this machine, LISSMAC is setting new standards with its focus on deburring and, in particular, deburring small parts. The machine also achieves significant time savings through machining on both sides simultaneously.

The deburring machine is suitable for deburring laser parts and rounding edges. Inner and outer contours can be machined in just one operation. When deburring, a cross-sanding belt works on the surface of the material. Burrs and surface splashes that can occur during punching or laser cutting are completely removed. All workpiece edges, on the outside and inside contours, are rounded evenly by two rotating, flexible grinding flap rollers. Secondary burrs are also effectively removed, while galvanized surfaces or protective films are not destroyed.

Technical Data

| SBM-XS G1E1 | |

|---|---|

| Working width max. | 300mm |

| Workable material thickness | 1.0 – 15 mm |

| Voltage | 400 V / 50 Hz |

| Network Structure | 3~ PEN / 3~ PE+N |

| total current consumption | 13.5 A / 14 A |

| total power | 7.5 kW / 8.5 kW |

| insulation class | IP 42 |

| infinitely variable feed speed | 0 – 2M / min. |

| weight approx. | 1400kg |

| dimensions (W/D/H ) approx. | 1300 x 2300 x 1900 mm |